Compressors are machines that are used for various types of jobs in terms of printing technology. There are different types of compressors used for other processes.

The screw compressor is one of the most efficient types of compressors used for various refrigeration and air processes. For more information about screw air compressors, you can explore this link.

Image Source: Google

It has also been used for various process applications for some time. Over the past two decades, screw compressors have gained immense popularity in the natural gas industry and various gas storage applications.

Most industrial applications are identical to reciprocating compressors, but costs and complications have prompted us to look for suitable alternatives. These screw compressors are under development and are therefore a suitable alternative for industrial use.

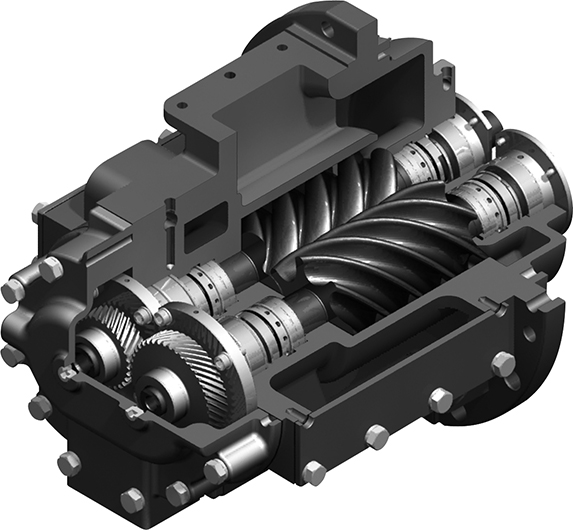

The screw compressor is one of the compressors with excellent mechanical properties and one of the compressors with positive volume.

It is designed with several simplified parts that allow it to effectively compensate for the gas forces exerted on the screw.

Equipped with bearing brackets that support the gate rotor.

Many components assist in the basic operation of a screw compressor. Getting an overview is very effective as it helps to understand the whole mechanism.

The screw compressor has an air tip that compresses the air. They are built with precision and require appropriate system knowledge.

Comes with two screws:

The larger screws are called feminine while the others are called masculine.

The inner screw rotates through the electric motor.

Female screws are relatively stronger than male screws.

The main purpose of the compression stage is to compress the oil-air mixture.